JUMBO BAG / BIG BAG

The amazing packing concept

During the last 25 years, the use of flexible intermediate Bulk Containers increased considerably. The main reason for this quick development is the simplicity of filling procedure, transportation, storage and discharging in comparison with small bags.

FIPCO is proud to offer jumbo bags that meet your requirements at very competitive price. At FIPCO, we are putting the needs of our customer first. The quality of our products and our customer service has made us a leader not only in the Middle Est. but worldwide and for that our vertical integration gives us a first class standard for consistency and reliability.

Advantages of Jumbo Bags

Our Jumbo Bags provide modern and efficient way of packing, handling, storage and transport of lumpy and very fine materials in bulk quantities such as petrochemical by-products, fertilizers, cement, sand, minerals, grains, feeds, seeds, etc. These are available in three structural types such as the single, double and four loops with different styles of construction of the filling and discharging spouts.

our Jumbo Bags are designed to attain 6:1 safety factor with capacities ranging from 500 to 1,200 Kgs. and 2,000 Kgs. for special cases from flexible and heavy duty polypropylene materials.

FIBC Baffle Bag

As the standard bag will round out on filling, a design has been created which reduces this effect through the use of internal baffles to provide tautness without in any way reducing capacity.

This baffle bag will cut down on space requirements, thereby also lowering freight costs by as much as 30%.

FIBC UN Bag

The transportation of hazardous goods is regulated worldwide by a team of experts from the United Nations.

They have established directives to prevent accidents, injuries and damage to property and not least to protect public health and prevent pollution. We test and design the bags so that they comply with all the requirements of a UN FIBC.

This work is done in our own testing laboratories and is then ultimately certified officially by repeating the tests in an independent testing facility. The test results are the basis on which a unique UN number can be issued.

FIBC Conical bag

The conical bag is designed specifically to assist in complete discharge of contents which are slightly sticky [like brown sugar].

To facilitate use and transportation of the bag, different options are available for closure, filling, discharging and lifting.

FIBC Tunnel Loop Bag

The unique design of tunnel loop bag with 2 side tunnels helps the customer in reducing labor cost.

The core advantage of this side tunnels is that it would require only one person to handle the FIBC and facilitate easy manipulation of the FIBC with a fork lift and also reduce the pallet usage and also trimming down the time and cost when filling and handling.

Type C-Bag

Type C-Bag Conductive

Standard: lEC 61340-4-4.

Special Use: For Transporting of dry, flammable powder.

These bags are safe when grounded because any electrostatic potential that builds up as a result of rapid filling or discharging quickly Electro-Static potential that builds up as a result of rapid filling or discharging quickly and safely exits the bag to ground via the network of conductive fiber woven into the fabric of the bag.

Using type C or Ground able FIBCs can be a very effective guard against electrostatic discharges as long as the bags remain grounded during both filling and discharging of product.

Anti-static Type “C” Bag

Type C FIBCs are constructed of fabrics with conductive carbon threads, woven into them no more than a certain maximum allowable distance apart.

These threads create a faraday cage, therefore, when one part of the bags is connected to a grounding cable, or comes into contact with any other conductor that is grounded, the entire bag then becomes safely grounded. Even though all of the product does not contact the conductive threads, the spacing of these threads is such that any isolated charge that develops on the surface of the bag is drawn towards the grounded threads, effectively naturalizing that charge.

Type’s C Jumbo bags refer to the class of FIBCs that actually protects against dangerous static discharges through grounding of the bag itself during the filing and discharging processes.

If the bag becomes ungrounded during either of these processes for any reason, it can create an extremely dangerous and explosive situation great care must be taken by operators to insure a positive ground is achieved and maintained before beginning to use the FIBC. When used correctly and consistently, type C-bag can be used in nearly any flammable or combustible environment with very low MIEs [Minimum Ignition Energies].

FIBC Four Loop Bag

Used in various industries. Designed both for 4 point and 1-2 point lifting with some additional accessories.

Commonly used for fertilizers, cement, milk powder, granules, powder minerals, fish food and animal feed.

They are designed for 1 and 2 point lifting. Mostly used with polyethylene liner.

Lifting

Used in various industries. Designed both for 4 point and 1-2 point lifting with some additional accessories.

Filling & Closure

- Easy for manual filling or big filling materials

- For construction material such as stones or sand which need no extraordinary protection.

- The universal system, it can be folded outside for easy manual filling.

- Attachable to nearly every filling station and diameter.

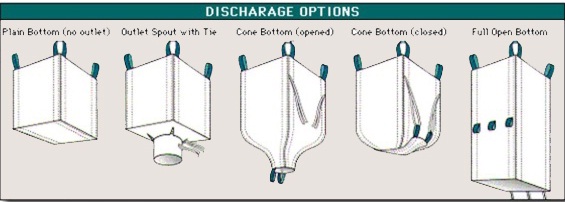

Discharge

Open bottom (For single or multi-usage bag)

- Bag with bottom discharging Valve or Spout for easy discharging materials.

- Standard coated to protect from dirt

A closed bottom (For single use)

- Just cut open manually or by a discharging apparatus or simply set on a FIBC-discharge equipment.

- Standard coated to protect from dirt